More than 25+ years of production experience, providing customized more than 3000+ sets scrap metal recycling schemes.

PRODUCT INTRODUCTION

Production detail: CBJ series hydraulic scrap bale breaker machine is suitable for metal recovery companies, scrap steel plants, smelting and casting enterprises to improve the quality of scrap iron and steel production to provide high-quality qualified charge production of professional equipment, CBJ series hydraulic scrap bale breaker machine is also known as press block decomposition machine, is a new generation of professional dismantling of scrap metal bales, a kind of testing equipment. CBJ series hydraulic scrap bale breaker machine can detect the impurities in the user package block, to ensure the content of scrap steel, to ensure the quality of scrap steel products, to maintain the stability of scrap steel market, CBJ series hydraulic scrap bale breaker machine is widely used in steel, smelting, steel, wharf and other industries. Features: ●CBJ series hydraulic scrap bale breaker machine has different specifications and models, which can meet the needs of different customers. ●A variety of machines can be added according to customer requirements ●CBJ series hydraulic scrap bale breaker machine don’t need to be fixed and installed ●Simple PLC operation, strong stability, high safety factor, completely separation. ●CBJ series hydraulic scrap bale breaker machine has Low noise, no vibration. ●High degree of automation, high productivity ●During the operation of CBJ Series hydraulic scrap bale breaker machine, do not repair, do not touch the moving parts, do not press the material in the material box with your hands or feet Working principle: CBJ series hydraulic scrap bale breaker machine supplies oil to the integrated oil circuit through the hydraulic plunger pump, and then transmits it to the hydraulic cylinder through the distributed manual valve to generate power. The pressure can be adjusted to the required rating according to the actual situation (the rating is shown by the pressure gauge).The hydraulic baler is separated by grasping and squeezing the hydraulic manipulator, and disassembling the bales through multiple decomposition. Main components: CBJ series hydraulic scrap bale breaker machine is composed of main engine, hydraulic system, manipulator, butterfly beam, oil tank, oil pump and motor.CHARACTERISTIC

Our CBJ Series hydraulic scrap bale breaker machine provide custom famous brand machine parts, we have been cooperating with many world-famous brand supplier, like SIEMENS, NOK OMRON, SCHNEIDER, CHINT, MITSUBISHI and so on for more than 10 years

PRODUCTIVE PROCESS

SHIPMENT

The minimum model Our CBJ Series hydraulic scrap bale breaker machine can be protected well in one 40 HQ container. If ship by boat, we will cover the poncho and Load deck to protect our CBJ Series hydraulic scrap bale breaker machineCOOPERATIVE SUPPLIERS

TECHNICAL PARAMETER

| Model | Nominal pressure (Ton) | Removable bale size(mm) | Power (KW) |

| CBJ-1200 | 120 | ≤ 600 x 600 | 18.5 |

| CBJ-1600 | 160 | ≤ 800 x 800 | 22 |

| CBJ-3150 | 315 | ≤ 800 x 800 | 45 |

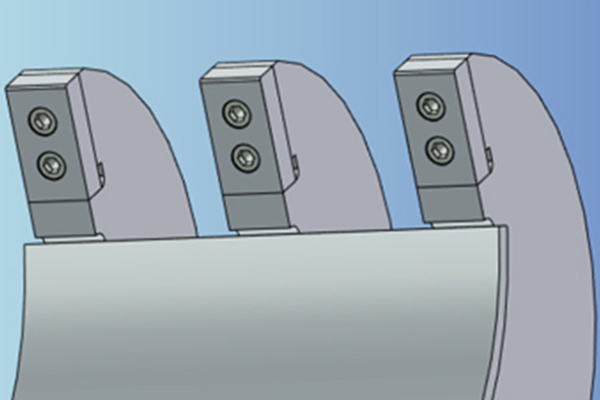

2.Replaceable claw head blade Replaceable high - strength alloy steel blade is used on the head of the claw, improve the wear resistance and service life of the hook claw.1.Easier to unpack CBJ series hydraulic scrap bale breaker machine adopted a more scientific hook and claw structure, the hook claws cut into the package better, making it easier to unpack.

2.Replaceable claw head blade Replaceable high - strength alloy steel blade is used on the head of the claw, improve the wear resistance and service life of the hook claw.1.Easier to unpack CBJ series hydraulic scrap bale breaker machine adopted a more scientific hook and claw structure, the hook claws cut into the package better, making it easier to unpack. 3. Wear resistant design of key parts guide rail According to the wear characteristics of the guide rail and other relevant parts of the frame, the high strength wear-resistant alloy steel plate is installed on the frame.

3. Wear resistant design of key parts guide rail According to the wear characteristics of the guide rail and other relevant parts of the frame, the high strength wear-resistant alloy steel plate is installed on the frame.

APPLICATION