The mixer is efficient and reliable; it delivers superior mixing quality and optimization of the blending process. The Mini Cyclomix can improve the homogeneity of an inhalation powder mixture by significantly reducing particle size and increasing the surface area of the particles. Therefore, this is the ideal tool to produce a highly uniform and consistent formulation, which is key to achieving optimal inhalation efficacy.

The alligator shear technology is what sets the Mini Cyclomix apart. The alligator shearing effect is achieved by a patented rotor and stator assembly, which creates distributed high shear stress in the material. The high shear forces applied during the mixing process, coupled with the alligator shear effect, result in a significant reduction in particle size, which translates to better patient outcomes.

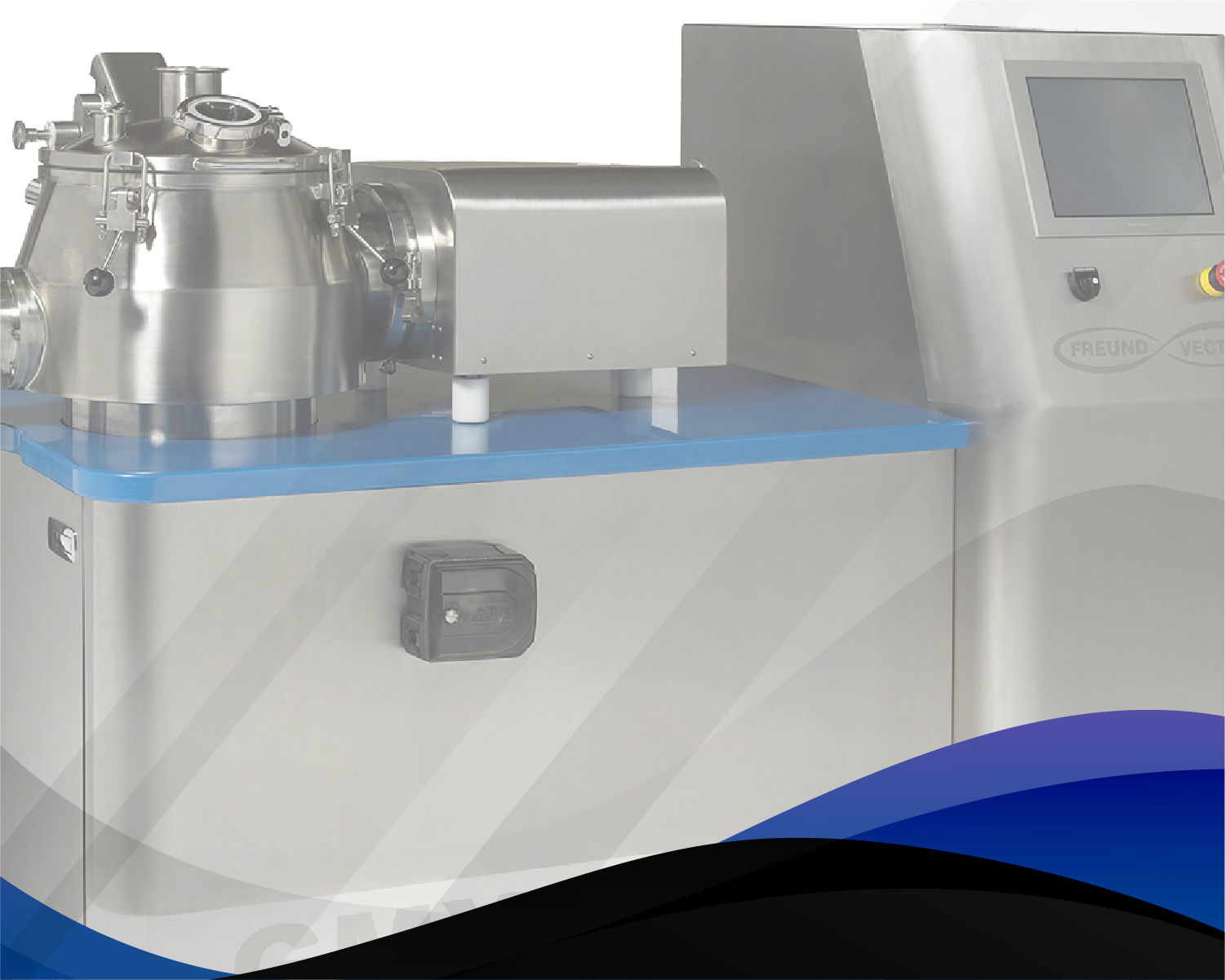

Another key feature of the Mini Cyclomix is its cleaning process; this mixer is designed to be easily cleaned and sanitized, preventing cross-contamination between batches. Its compact size means that there is less surface area to clean, leading to improved cleaning times and reduced risk of contamination.

Overall, the Mini Cyclomix high shear lab mixer is a reliable and efficient tool for producing homogeneous dry powder inhaler formulations. Its alligator shear technology stands out as a unique and innovative process, which ensures optimal particle size reduction and an improved surface area of the particles. Its market reputation and the consistently excellent results it delivers prove that the Mini Cyclomix is an industry leader.